The modern vehicle has become a data center on wheels. With embedded MIPI interfaces and the reprogrammable Quantum® fabric, Efinix® FPGAs are uniquely positioned to address the needs of automotive applications.

The automotive industry is going through a period of rapid evolution and that is posing a unique set of challenges. Automotive electronics are changing at a rapid pace with innovations in every aspect of the vehicle from driver assistance and autonomy to passenger experience, safety, and infotainment. Even the electronic drive train itself is evolving. Technologies such as advanced displays, sensors, and artificial intelligence are finding their way into vehicles and those same technologies and standards are advancing with increasing speed.

The unique challenge with the automotive industry is that, unlike the rapid typical consumer electronic design cycles, automotive design cycles are extremely long and burdened by time consuming and expensive certification requirements. Entire generations of electronic features can be designed into a vehicle and become obsolete before the vehicle enters production. What is needed is a hardware platform that can adapt to evolving requirements during the vehicles design cycle, absorbing new technologies and techniques while providing a stable hardware configuration for certification.

Applications up to ASIL-B are excellent targets for FPGAs. The explosion in the complexity of automotive electronics means that there is no shortage of ASIL-B applications in the modern vehicle.

Click to view the FPGAs' application in the automotive industry.

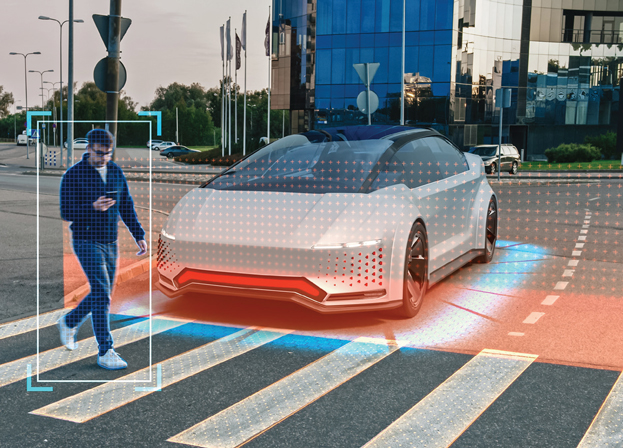

Driver assistance advances have caused a proliferation of sensors around the vehicle, from long and short range radar on each corner to forward and surround cameras. Each sensor needs to pre-process data and then extract it from complex and often artificially intelligent algorithms. Sensor fusion and real-time, low-latency data processing are key areas for implementation in FPGAs.

Camera monitoring systems provide more information to the driver or provide situational awareness. Camera monitoring systems in the vehicle itself can feed algorithms to monitor the driver or vehicle occupants. These algorithms demand large amounts of parallel compute power. Dynamic and reconfigurable FPGAs can keep capabilities up to date during the long automotive design cycle.

Increasingly displays are replacing traditional gauges for the driver and provide a wealth of additional information that would otherwise be unavailable. The passenger experience is augmented with large screen infotainment capability. Again, FPGAs provide the perfect platform for display management and deliver a future-proof dynamic platform for video and audio CODECs.

In this case a camera monitoring system replaces a traditional rear-view mirror, adding significant value for the vehicle operators and drivers. The FPGA can also support AI-enhanced applications such as trailer tracking or digital assistance.

Ti180J484

Efinity® Software

Efinity® Software The Efinity® software provides a complete RTL-to-bitstream flow. With a simple, easy to use GUI interface and command-line scripting support, the software provides the tools you need to build designs for Titanium and Trion® FPGAs. We provide free licenses for the Efinity software that includes a wide range of IP cores, including our popular Sapphire RISC-V SoC.

The following Efinity software versions are ISO-26262 certified and supports designs up to ASIL-D, the highest level.

ISO-26262 certified versions:

Windows and Linux versions are certified

ISO-26262 certified Efinity tools:

Efinix-provided IP cores are not ISO-26262 certified.

I'm Interested!

Fill out this form to learn more about our automotive program:

For this project, the Titanium Ti60 FPGA replaces a micro-controller and CPLD in one of the main vehicle control units (VCU). The design features the embedded Sapphire RISC-V SoC and custom instructions. The redesigned VCU uses fewer components and has low power consumption, as well as a dramatic improvement in processing capability.

Ti60

Increasing automation is driving up the requirements for resolution and range, increasing the specifications for the point cloud and real time computation. With more and more LiDAR units finding their way onto vehicles there is a need for smaller footprints and lower power.

Ti60F225Q3

Trion and Titanium FPGAs support a high-performance, customizable RISC-V processor. Even if the RISC-V software is intercepted and stolen, it will not run on anybody else’s system because it contains references to the FPGA's custom and unique elements.

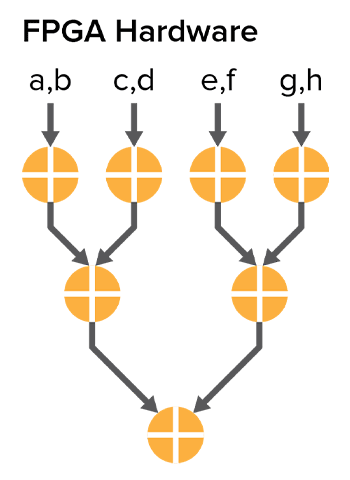

FPGAs are not constrained by traditional sequential processor architectures. They can process data in parallel and in real time. FPGAs are particularly good at real-time applications where deterministic response with low latency is needed.

All Titanium devices include both encryption (with the AES-GCM-256 algorithm) and authentication (with the RSA-4096 algorithm).

The configuration itself is encrypted so it cannot be reverse engineered or stolen and changes cannot be meaningfully applied to it.

One aspect for designing automotive systems is high reliability—systems are required to perform for several years without environmental eff ects like single event upsets (SEU).

Titanium devices can monitor device integrity. You can design your application to recover from random SEU events, ensuring maximum uptime.

Data Sheets

Efinity User Guides